Working in a Good Laboratory Practice (GLP) environment means your lab needs more than written procedures. Protecting people, keeping data accurate, and maintaining trust with inspectors all depend on clear, practical OSHA training in GLP labs that staff actually use every day.

OSHA training plays a huge part in this. In a GLP lab, employees face daily risks like chemical spills, biological exposure, equipment accidents, and even fire hazards. Knowing how to recognise these dangers and respond the right way is essential, not just to stay compliant but to prevent incidents that can damage your research, products, or reputation.

This blog explains what OSHA expects from labs operating under GLP principles, who needs training and when, and how to build a training program that holds up under inspection and truly keeps your people protected. Whether you are setting up a new lab, bringing in new staff, or improving your existing program, these fundamentals will help you build a safety culture that lasts.

In a GLP-compliant lab, safety and data integrity go hand in hand. Every result, sample, and record must be accurate and traceable, and that level of control depends on people doing their jobs safely and consistently. A single chemical spill, improper PPE use, or ignored hazard can put employees at risk and ruin valuable research.

OSHA training helps prevent these mistakes by giving staff a clear understanding of the hazards they might face and the right steps to take if something goes wrong. It builds habits that keep people alert to risks instead of cutting corners.

Regulatory inspectors expect more than a generic sign-in sheet or outdated safety video. They want to see proof that training is practical, up to date, and matched to each role in the lab. When your team can explain safety procedures confidently and apply them correctly, you show that your lab takes both people and product integrity seriously.

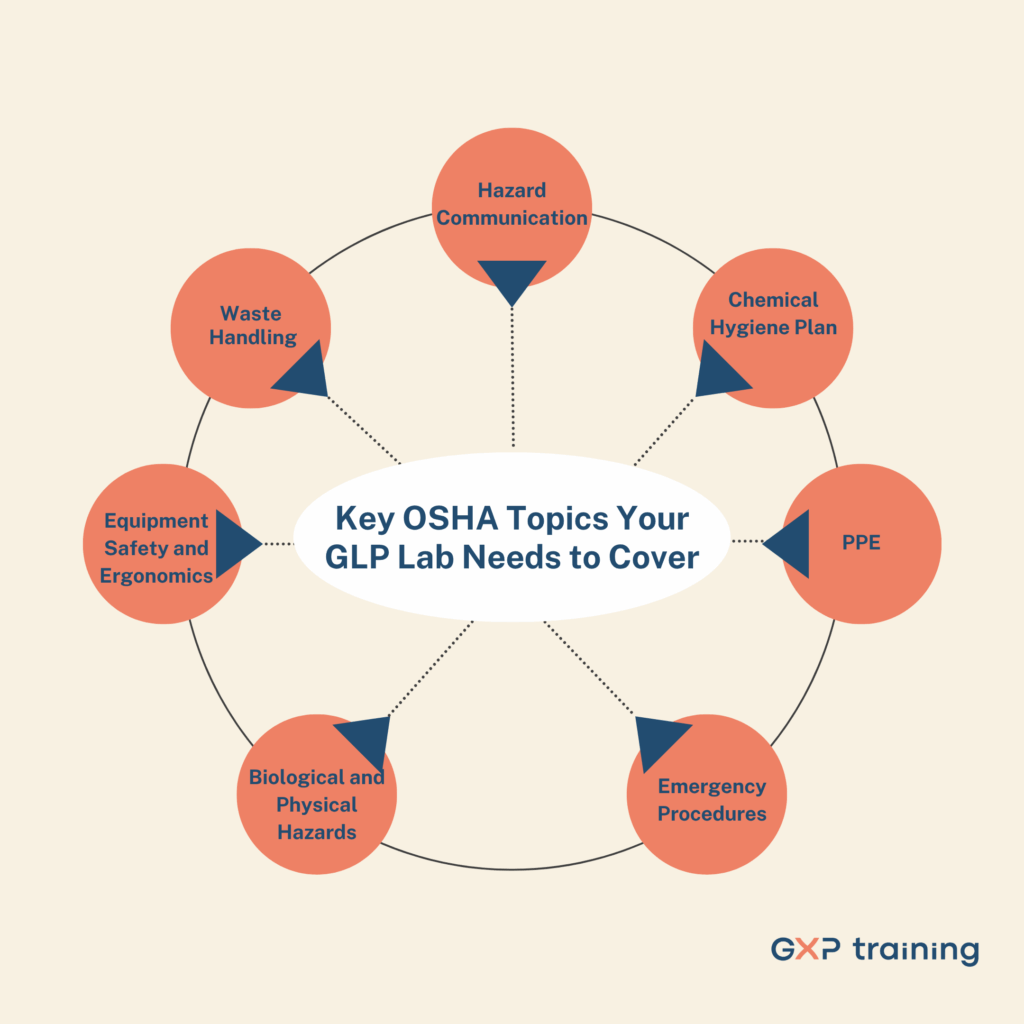

Your OSHA training program should match the real risks your lab staff face every day. Covering these essentials helps protect people, data, and compliance.

A strong program that covers these areas makes safety second nature, reduces risks across the board, and shows inspectors that your lab puts real care into protecting people and the work they do.

Our OSHA Lab Safety Certified Training is built for life sciences teams working in GLP-compliant labs. It breaks down complex OSHA standards into clear, practical lessons that staff can apply confidently on the job.

Your team will complete the training with a CPD and CEU-accredited certificate that proves they understand how to recognise hazards, manage risks, and keep your lab safe and compliant.

Key features include:

A trusted course like this gives your people the knowledge and confidence to handle risks properly and helps your lab stand up to inspections with no surprises.

OSHA training in a GLP lab should stay current with how your work changes. When you bring in new chemicals, new equipment, or update procedures, your team should be shown exactly what’s different and how to handle it safely.

Most labs stick to an annual refresher because it helps people stay sharp and gives everyone a chance to revisit key safety steps together. It’s also an easy way to show inspectors that you keep safety knowledge up to date for all staff, not just new hires.

Staying on top of training means your team is more prepared to handle problems when they happen, and that makes your lab safer and inspections much less stressful.

Too often, safety training sits in a binder while real lab work goes on as usual. In a GLP lab, that approach doesn’t work. For training to stick, it has to feel practical, relevant, and connected to everyday tasks.

One way to make this happen is to use real examples during training sessions. Instead of just listing steps for a spill response, show where the spill kit is, practice how to use it, and review what happens after the cleanup. If your team works with biological samples, walk through how to dispose of waste correctly and why each step matters for both safety and data integrity.

Short, routine reminders also make a big difference. Start meetings with a quick safety check. Use five minutes to discuss a recent near-miss or walk through how new equipment changes the way a task is done. These small moments help people remember what they’ve learned without adding more formal training sessions every time.

A strong safety culture is built on people feeling confident enough to ask questions or point out when something doesn’t look right. When staff know they can speak up without being blamed, you’re more likely to catch problems early. That attitude is what inspectors look for too: clear evidence that your team understands their responsibilities and applies training in real work.

The labs that succeed in safety do more than meet the minimum standard. They keep the lessons alive, so good habits stay strong even when the workload picks up.

Our OSHA Lab Safety Certified Training gives your GLP teams the practical knowledge they need to keep people safe and protect your data and compliance record. When staff understand exactly what’s expected, they make better choices and avoid mistakes that could turn into bigger problems.

If you’re ready to strengthen your entire safety culture, explore our training library and see how we can help you build a program that truly fits the way your lab works.